| 30 DAYS MONEY BACK GUARANTEE | FREE U.S. SHIPPING $50+ ORDERS* |

| 30 DAYS MONEY BACK GUARANTEE | FREE U.S. SHIPPING $50+ ORDERS* |

Keepfiling Sheet Protector Buying GuideComplete guide for buying Keepfiling sheet protectors

Even with something as simple as sheet protectors, there are several points you should consider when buying them. Keepfiling wants to make it easy for you to choose the right sheet protector. Follow this guide to learn about Keepfiling sheet protectors and it will help you pick the type of sheet protectors you need.

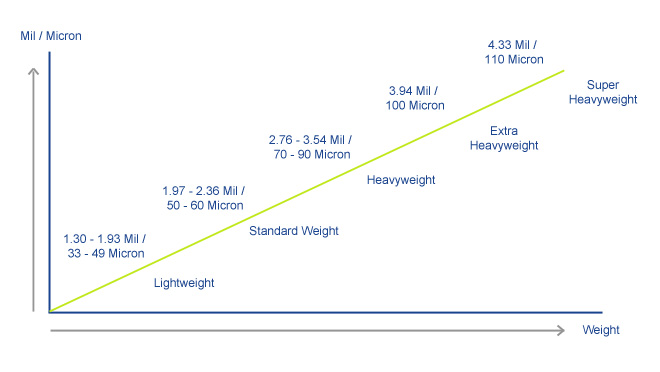

Sheet Protectors Weights - What Weight to Choose ?We There are a lot to take into consideration when choosing the weight or should we say the thickness of the sheet protector, file jacket or plastic sleeve. However for a fast guide to the five main categories that are the most widely used within the industry we recommend as written in the table below.

Material Gauges for Sheet ProtectorsThis is detailed information about sheet protector weights and the material gauge used, also a bit of a historical reference. It will also get into the sensitive issue about how not to get cheated or at least not to feel cheated when receiving the final purchase.The truth is that a some manufactures and dealers sell polypropylene sheet protectors under the pre-text that they are HEAVY WEIGHT when they in reality upon receiving the ordered sheet protectors or page protectors the shopper find what they got was a thinner gauge more like a STANDARD WEIGHT sheet protectors or less. Now there does not exist a "higher council" for determination of weight definition for sheet protectors or pages protectors. However with the following we have set a standard based upon many years of experience working in this field at a professional level. We can only emphasize to look for or request the material gauge from your supplier before you make your purchase. If material gauge is not displayed one easy way to compare is to look at the actual shipping weight per 100 pages. It should NOT be less than what has been written below:

The above is our set standards, we display with every single item the products thickness in micron as well as Mil (see Quality listing under each item). It should also be noticed that manufacture or re-sellers display the products thickness in Mil with only one digit and then round the numbers up. Mil being a fairly rough unit of measurement for something as thin as sheet protectors can easily be rounded up to display a more favorable material thickness. Where micron being 10.000 parts per centimeter or app. 2-1/2 time smaller than 1 inch is a much more accurate term for measurement but being a metric term we have never had a tradition for using this measurement in the United States perhaps with the exception of within certain industries and within the NASA space program where metric was not easy to implement, which is a different story. However to make it simply we have listed both terms of measurements as to highlight the differences in the following. The above standards in the table are used more or less by most major manufactures with in +/- 5 micron or so. However for super heavy weight sheet protectors 5 micron is so little that most people cannot feel the difference. However 5 microns difference between a standard weight and economy weight model makes a lot more difference as the products stiffness is lost and the sheet protector becomes less handy to work with. In short, as the gauge increases (either in Mil or Micron), the weight increases:  DON'T WANT TO GET CHEATED?Look at the product shipping weight. If it say 1.66Lb per 100 sheets you have a good Standard Weight sheet protector but is the weight listed as 1.70 Lb for 100 Heavy Weight sheet protectors and perhaps listed as a "special polypropylene mix" or similar "salesy" words we would recommend that you check twice and get an actual measurement of the material thickness before you make your purchase.In today competitive world where even the biggest brand name manufactures fight to "get the sale" the consumer is easily forgotten and the old ethics of selling a good descent product at a fair price. As always there are a connection between price and quality and if the deal look too good to be true you may be better off in the long run to take your business somewhere else. Remember: Only serious manufactures and dealers list material thickness. Hope you find the above information useful. Feel free to browse our wide range of sheet protectors now.

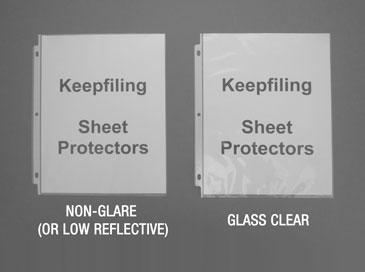

Glass Clear vs. Non-GlareFor the most popular models, Keepfiling carries both glass clear and non-glare (low reflective) type sheet protectors. But which to choose and why offer two models?There are advantages for both type of clarity. However often it falls to personal preferences but here are a few points why you may prefer one type over the other. Glass ClearThe most clear of the two textures. Preferred when photos or color printed materials are to be displayed. Colors are shown more vibrant and rich in glass clear pages.The disadvantage is that the clear surface of the material will reflect light easier from surrounding light sources which can make it a bit uneasy to read through in the long run. In addition, finger print marks are easier shown on this type of material but of course can be easily cleaned off. Non-GlareThis material type is often also called low reflective. Back in time non-glare was more frosted in the surface but eventually it has evolved into today's type of material which in comparison is a bit more dusty. Most major brand names use this type of material today. At Keepfiling we prefer the term low reflective as these pages are more suitable for written material and, black and white print.The inserted documents are displayed as a bit more dusty compared to the glass clear material. It is this 'dustiness' that makes the low reflective surface easier for reading as it is less straining for the eyes because less light is reflected of the surface compared to glass clear material. Finger print marks and scratches from daily usage are not as obvious on the non-glare material. Keepfiling offers the letter size (8-1/2 x 11) sheet protectors in the above two material types. They can be found here:

Below we have a text document inserted into both the non-glare and glass clear sheet protectors. As you can see both text documents are very readable, and the only difference is that the glass clear gives out more reflections (notice on the top and bottom of the sheet protector). The non-glare has a bit of a 'dusty/murky' feel to it.  Here we have a colored documents inserted into the sheet protectors. You'll notice that the glass clear material clearly brings out the colors of the document and is very crisp. Whereas the non-glare, again, has a very 'dusty/murky' texture that dulls the colors of the document.  Please note that it is difficult to show on screen the real clarity of the two materials, so only take these photos as a reference to how they might look in person, and also note that all documents were printed on copy paper with an inkjet printer. Material Thickness and the Clarity of the PagesThe thickness of the material also plays a small part in the clarity of the sheet protectors. Technically speaking, the thicker the material means that less light will be able to penetrate through and therefore the result is a more dull view. However, most users will not be able to tell the difference in clarity between the different thickness of sheet protectors.Despite what we have said, there is no right or wrong to which clarity you should be using for your documents. At the end of the day, if comes down to personal preferences. Some customers may prefer the non-glare material because they think the 'dusty/murky' texture reflects less light and will be easier for the eyes to read. On the other hand, some customers may not like it because it's not clear and will think it's not 'crisp' enough for the document it's hold, therefore they will prefer the glass clear material. Rip Free HolesMaterial thickness also matter when it come to pre-punched pages. The pages need a reinforcement strip for the thinner gauges or their is no strength in the hole edge and it easily get caught in the binder rings where the two parts meets. The hole edge will fold and rip. This is in particular the case with pages less than 60 micron in thickness. For pages 90 micron and above reinforcement strip is really not needed it is more a case about visual look. We will however never recommend pages without reinforcement strip less than 100 micron this to be on the safe side. Enjoy your binder use quality pages.

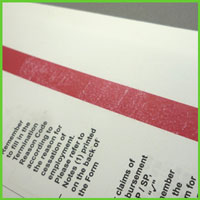

Archival SafetyThe use of sheet protectors with binders is not just about organizing, but should also be about archival safety and how the material of the sheet protectors will protect your documents. All Keepfiling sheet protectors are made with polypropylene which is one of the materials considered to be archival safe. Other materials that are archival safe are polyester and polyethylene. Among the three archival safe materials, polypropylene (or PP) is considered to the be the most economical and safest material. It offers decent quality sheet protectors at a very reasonable price whereas polyethylene (or PE) is the cheapest material but offers poor durability and the quality is not that great, while polyester (or Mylar) offers great quality but is very expensive to produce.The reason why these materials are considered archival safe is because they do not contain plasticizers. Plasticizers are added to plastics to increase their flexibility and durability but the downside is it emits hydrochloric acids when the plastic deteriorates. This is not safe because over time, it's inevitable that there will be some deterioration to the sheet protectors you are using. If they contain plasticizers, the deterioration will cause hydrochloric acids to be released and this can severely damage your documents. PVC contains plasticizers and there are sheet protectors on the market that are made from PVC. These sheet protectors are therefore not archival safe. Using them will cause damage to your documents over time, for example, colors on photographs might be damaged or text from printed documents will stick to the plastic destroying your papers completely. The images below shows exactly how PVC sheet protectors can damage both the document and the sheet protector itself. As you can see the ink is ruined on the document and is stuck onto the sheet protector making a mark. This can be a disaster if you've decided to use non-archival safe sheet protector as your documents could be ruined and will be very hard to restore. Avoid storing things like photos and and memorable items in PVC pages if you plan to keep them for a long time. The damage is irreparable.   - Damage done to both document and sheet protector from using PVC sheet protectors. For more information on archival safety, you can visit our Archival Safety Page or visit our main page and shop for our Sheet Protectors for Binders.

|